Why SWIX?

Traditional manual inspection methods are labor-intensive and come with inherent safety risks.

Unplanned works and scheduling complications often lead to increased maintenance costs.

Every year, the maintenance budget grows due to inefficiencies in the current system.

The shortage of skilled workers can result in further delays and risks.

Our Solution

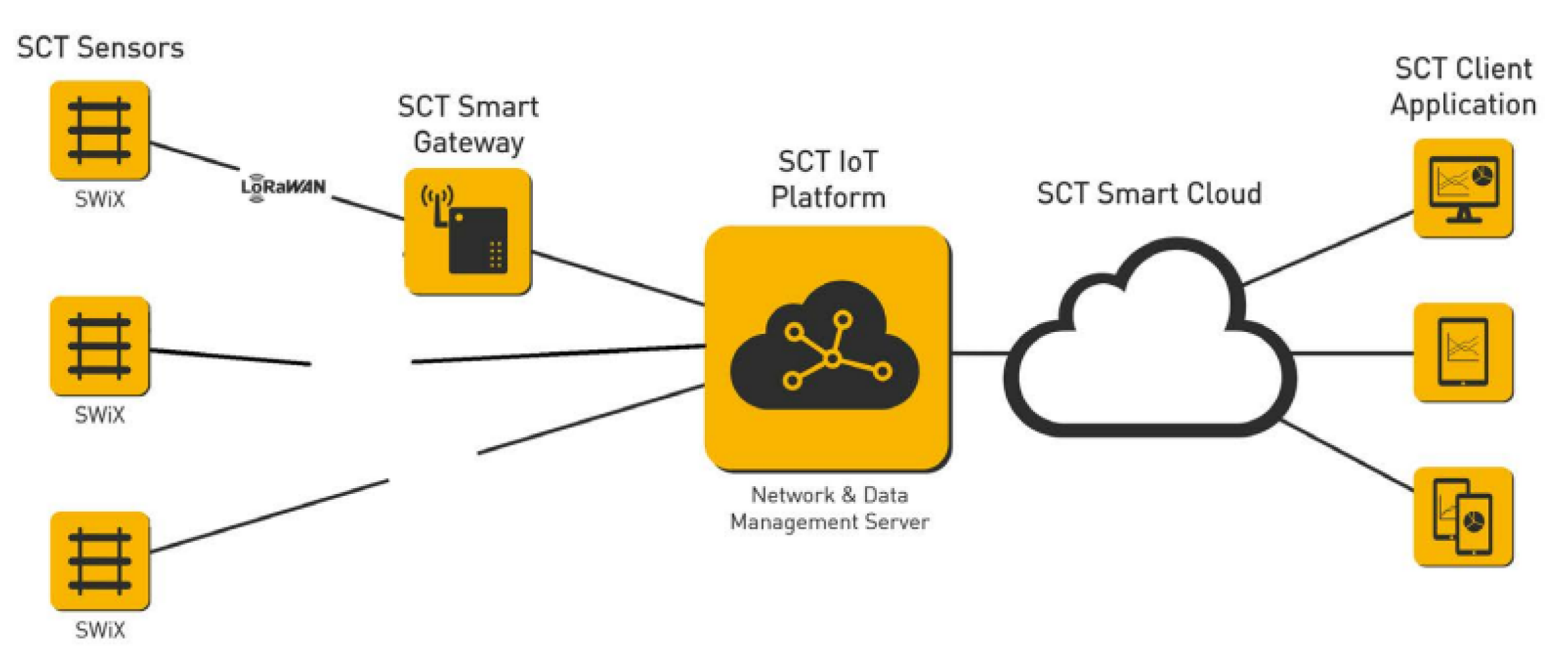

Strategic Monitoring: We place SWIX Units at critical track areas, ensuring comprehensive coverage and real-time data collection.

Advanced Measurements: SWIX Units measure vertical displacement and the impact force every time a train passes over. This real-time data collection ensures timely and precise insights.

Cloud Integration: Data is transmitted to the cloud where it’s analyzed to calculate an impact score, providing actionable insights.

Empowering Engineers: Our system offers crucial information to maintenance engineers, helping them make informed decisions for better track health.

Request a quote

Contact Us

+61 402 689 989

NOA Tech Pty Ltd

#151C Canna Drive,

Canning Vale WA 6155

Schedule A Call

Contact Us

+61 402 689 989

NOA Tech Pty Ltd

#151C Canna Drive,

Canning Vale WA 6155